Common mistakes to avoid when using ESD wipes in cleanrooms

Ensuring optimal cleanroom maintenance in electronics manufacturing is pivotal for maintaining product quality and minimizing contamination risks. Within these controlled environments, ESD wipes play a vital role in static control and contamination prevention. This article will explore how to effectively utilize ESD wipes, common mistakes to avoid, and how Lindström’s cleanroom service can enhance your operations.

Why are ESD wipes essential in cleanrooms?

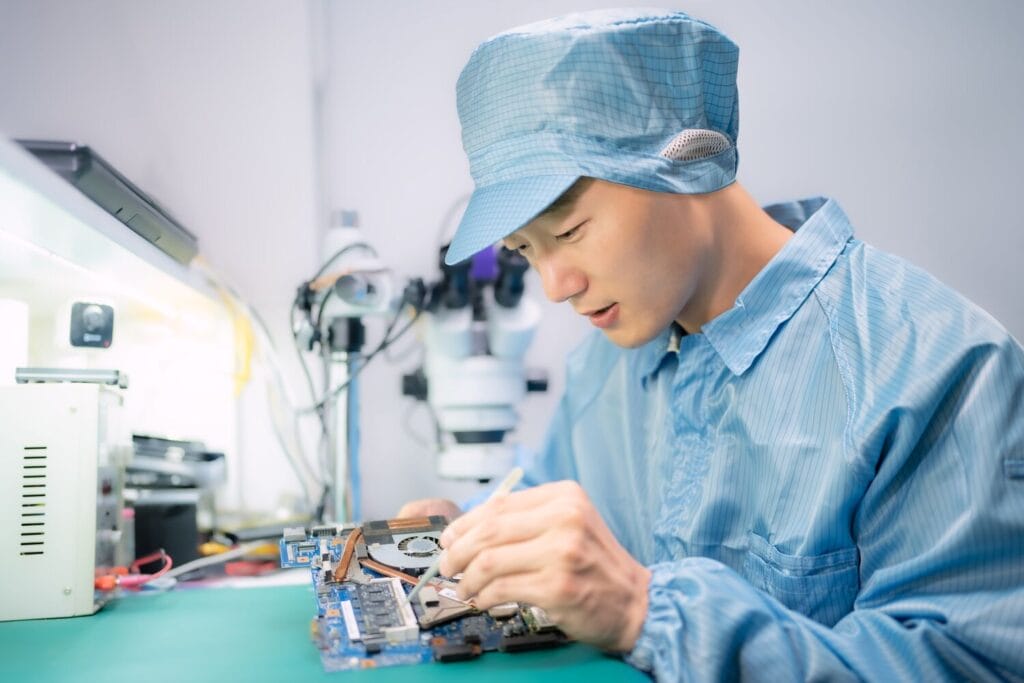

ESD wipes are indispensable in cleanrooms, particularly in electronics manufacturing facilities, because they help control electrostatic discharge (ESD), which can lead to serious damage to sensitive electronic components. By reducing static electricity, ESD wipes prevent contamination and ensure product integrity. Implementing ESD wipes as part of your cleanroom maintenance routine supports both static control and contamination prevention, ultimately enhancing the quality of your products.

In cleanrooms, any contamination can result in costly defects and decreased efficiency. ESD wipes are engineered to remove small particles and residues, which are critical in maintaining a pristine environment. This is especially important when handling esd garments, esd smocks, and antistatic coats, all of which require a clean and controlled environment to function effectively.

What are the common mistakes when using ESD wipes?

Despite their importance, several mistakes can occur when using ESD wipes. One frequent error is inappropriate selection. Not all wipes are created equal, and choosing the wrong type can lead to insufficient static control and increased contamination.

Incorrect wiping techniques are another common issue. Improper methods can redistribute particles instead of removing them, negatively impacting cleanroom efficiency. Additionally, neglecting the regular replacement of ESD wipes can result in residue build-up, further compromising cleanroom conditions.

These mistakes can jeopardize product safety and efficiency, underscoring the need for proper usage of ESD wipes to maintain cleanroom standards.

How to choose the right ESD wipes for different cleanroom classes?

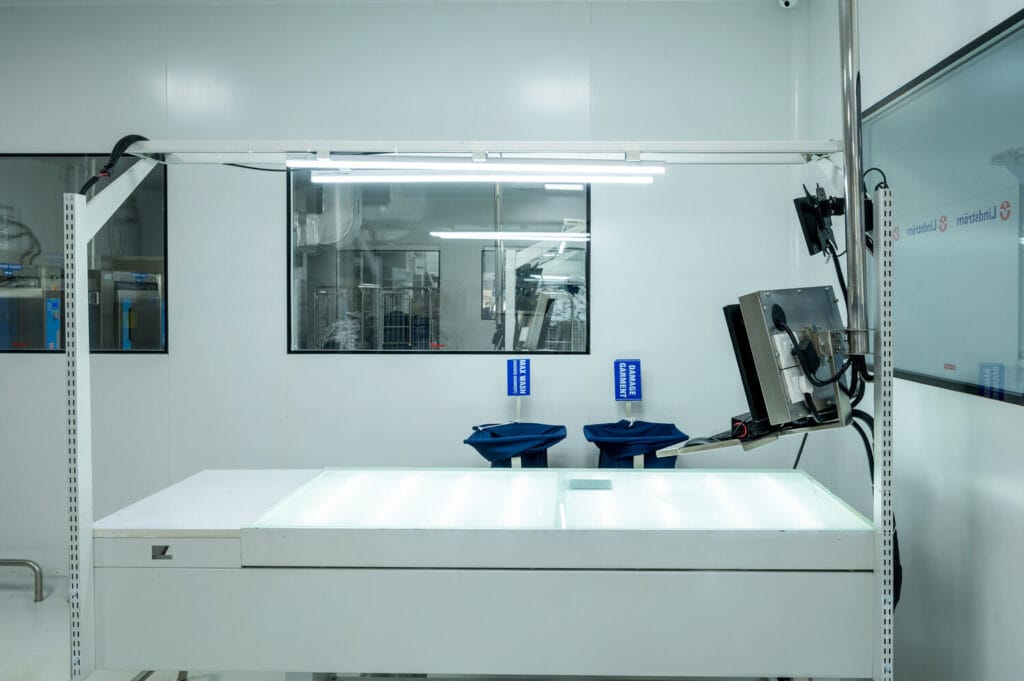

Choosing the right ESD wipes involves understanding your cleanroom’s classification and specific requirements. Different cleanroom classes have varying levels of allowed particulates, which dictate the type of ESD wipes needed.

For higher-class cleanrooms, opt for wipes with minimal shedding and superior cleanliness. It’s crucial to select wipes that align with the standards necessary for your cleanroom environment to ensure effective static control and contamination prevention.

Consider the materials and manufacturing process of the wipes. High-quality ESD wipes should be compatible with other esd garments, such as esd smocks and antistatic coats, to provide comprehensive protection in your cleanroom operations.

Tips for effective use of ESD wipes in cleanrooms

Maximize the effectiveness of ESD wipes by adhering to best practices. Proper storage is essential; keep wipes in a clean, controlled environment to preserve their integrity. Handling should be done with care to avoid introducing contaminants.

Regular training for staff on correct wiping techniques and routine audits ensure compliance with cleanroom protocols. Effective disposal of used wipes is also crucial, as improper disposal can lead to contamination.

Incorporating these practices into your cleanroom maintenance routine will help maintain a high standard of cleanliness and efficiency.

Understanding ESD and its impact on cleanroom environments

Electrostatic Discharge (ESD) is a sudden flow of electricity between two electrically charged objects. In cleanroom environments, ESD poses a risk of contamination and damage to sensitive electronic components.

ESD can lead to product defects, reduced efficiency, and increased costs. ESD wipes are vital in mitigating these risks by controlling static electricity and preventing particle contamination.

By understanding the dangers of ESD and utilizing ESD wipes effectively, businesses can maintain cleanroom integrity and protect their products.

| Criteria | Standard Wipes | ESD Wipes |

|---|---|---|

| Static Control | Minimal | High |

| Contamination Prevention | Moderate | Excellent |

| Cleanroom Compatibility | Limited | Optimal |

“ESD wipes are a crucial component in maintaining cleanroom standards and protecting product quality in electronics manufacturing.”